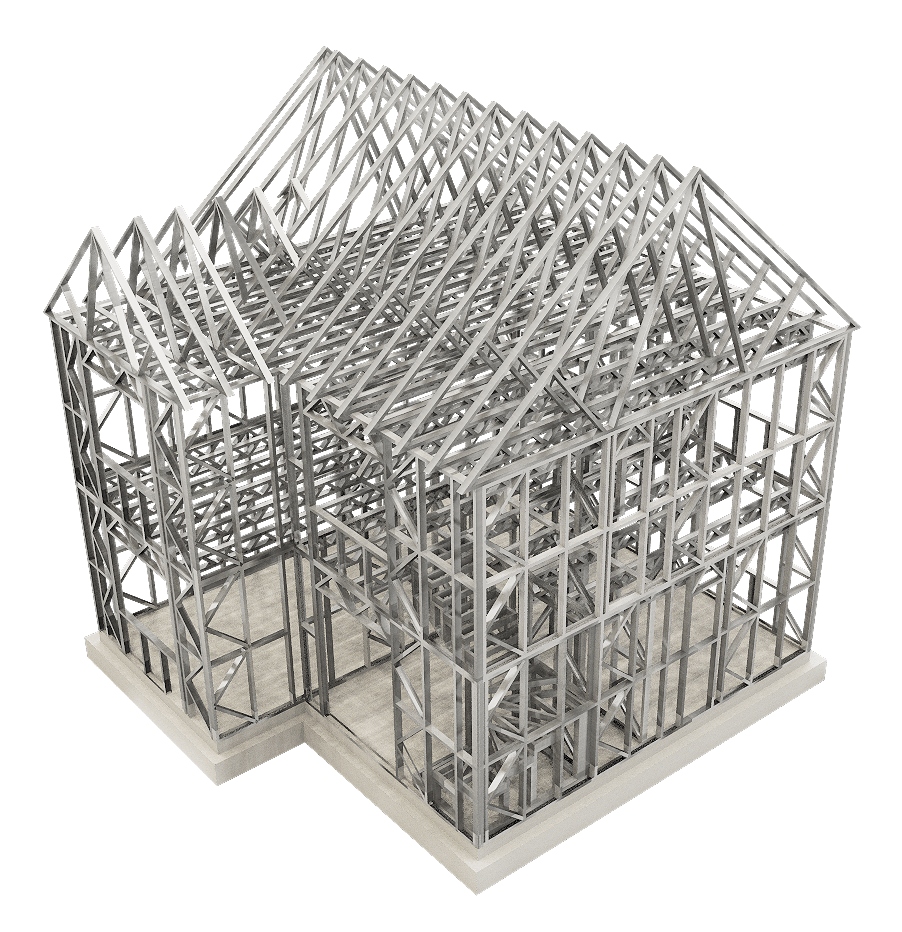

LGSF systems are becoming first choice of construction method for low rise MMC buildings.

It is widely accepted that Light Gauge Steel Frame (LGSF) systems are becoming first choice of construction method for low rise MMC buildings.

Steadily growing costs of traditional construction methods has put the spotlight on LGSF systems as the industry searches for new ways of working to beat the rise. We are now in the midst of an industry evolution – the construction community is embracing collaborative working and deploying innovative technologies to increase efficiency and raise sustainability standards. Lessons learnt from manufacturing has seen a recent boom in offsite MMC solutions to meet the demand for cost-effective, sustainable homes.

The offsite manufacturing nature of LGSF structures naturally lends itself as the first choice for use in low rise buildings. Some of the key benefits include:

Safety first

LGSF builds shift the labour requirement from onsite to a controlled factory environment. Fewer operatives onsite reduce the risk of accidents with small efficient teams erecting the frames.

Build speed & programme certainty

LGSF can achieve up to a 30% reduction on programme when compared to traditional building methods and a vastly reduced dependency on ‘wet trades’ can ensure programme dates are maintained

Cost effectiveness. Cost certainty

Our research shows a potential cost saving of up to 20% can be achieved with reduced on-site build times, precise offsite manufacturing of structural elements and early design coordination. Allowing for improved cost certainty for managing budgets

Sustainability

Just by removing concrete, LGSF systems are immediately far more environmentally friendly (concrete is said to contribution up to 8% of the world’s CO2 emissions). Minimal site waste and highly recyclable materials make LGSF structures one of the most sustainable construction methods available today.

Flexibility

LGSF systems can accommodate almost any architectural design both residential and commercial. Specific site constraints (typically access issues) can easier be overcome, adapting the design to suit.

Early access to follow on trades

a huge plus for clients especially those who have utilised LGSF on multiple projects. Once clients are familiar with the technology they are able to adapt their build programmes to enable early access for follow on trades. This facilitates huge reductions in overall site durations

Non-combustible

Light gauge steel structures are 100% non-combustible which is now a code requirement of all UK builds. Although steel can lose its strength in fire, if it is protected with suitable fire rated sheeting it can withstand the challenges of fire.

Durable & high quality

Steel can, quite literally last a lifetime. LGSF structures do not rot, shrink, warp or decompose. Unlike traditional hot-rolled options, the steel is galvanised prior to rolling. This offers unparalleled durability and removes the need for future painting and maintenance.

Optimised site management

As LGSF demands precise design and planning the exacting pre-construction phase helps enable more efficient project management, budget management and ultimately project management and timescale planning.